Mach is a manufacturing company that deploys products to ensure American dominance. Headquartered in Huntington Beach and backed by leading venture firms, we’re an engineering-obsessed team of 45 pursuing well-guided product bets to create value for the defense customer. We believe true capability starts at the sub-component level, so we aim to be the designer and manufacturer of full, vertically integrated supply chains. Different from system integration, subcontracting, or acquisition models, this full systems approach allows us to build the most optimized platforms at the lowest possible cost. We plan to use this vertically integrated flexible manufacture to create massive value–first and foremost in defense and ultimately beyond.

I founded the company by working as an auto technician to save money. Growing up and helping my grandpa on his farm in West Texas, I’ve loved manufacturing and industry my entire life and figured I could make things meaningful to the world. I took my $500 in savings, as well as a $200 seed check my parents wrote me, and started making things in two categories: 1) furniture, knives, tools, and other products to generate revenue, and 2) prototypes of technologies that I thought would be meaningful to national defense. I used the former to pay for the latter, which at the time included hydrogen guns, stratospheric balloons, unmanned aircraft, and electrolyzers.

When I went to college, I wanted to help national security. I was, and still am, incredibly concerned about America’s ability to fight a major war. I decided to enroll at MIT on an Air Force ROTC scholarship, where I would serve until I could scale the manufacturing work I’d done in high school. Between investors and recruits, I received far more traction than I expected, and I dropped out of MIT after my first semester.

In the short time since, Mach has gone through three distinct periods:

Pre-seed – Boston - 2023

- A team of three classmates and I researched my interests from high school in more depth. This time was a period of incredible learning, and we were able to quickly iterate and validate much of the technology.

Seed – Austin - 2023

- We built the team to ~35 full-time while exploring six potential products. Given the inherent difficulty of selling platforms to the DoD, I felt this multi-shot approach was the best way to de-risk the company.

Series A - Austin 2023 → Huntington Beach 2024

- Upon closing our Series A in October 2023, we decided to move the company to Huntington Beach to be closer to the best technical talent and better scale. Now that we had the capital to push products across the valley of death, we decided to ruthlessly cut products we weren’t 100% confident in and invest heavily in the ones we were.

The two products we’re investing heavily in are:

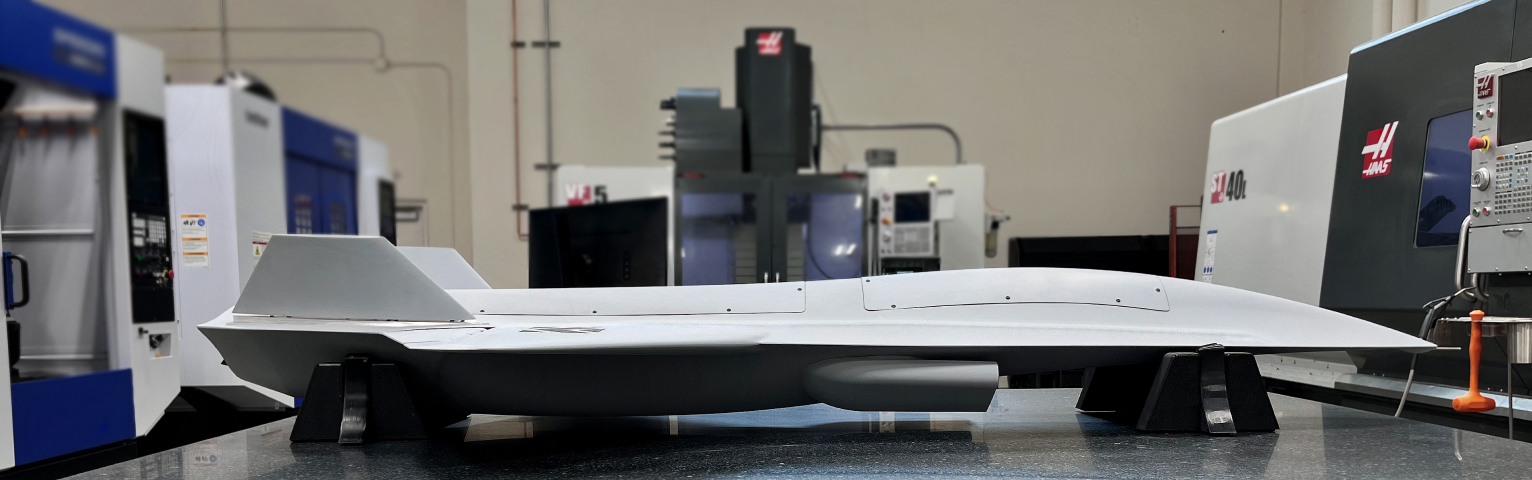

- Viper: Jet A-powered miniature fighter. We re-architected Viper from a 3D-printed miniature drone to a far more capable composite aircraft. We’ve since completed three more revisions in four months and are in active testing.

- [Redacted]: High altitude weapons platform - Invested in. We’ll share more about this program when we can.

We’re incredibly excited about Mach’s position. Viper, which we will first deploy as a cruise missile, will accomplish its role for less than 25% of the cost of the current state-of-the-art without any of the traditional centralized equipment. More importantly, we have a clear path to developing it as a capable Next Generation Air Dominance platform. Within the next 24 months, we look to make it an extremely capable stealthy, supersonic, VTOL fighter. We’re currently prototyping it at an airframe a day for well under $100k with an increasingly vertically integrated supply chain. Most exciting, we’re building our factory to manufacture at enough scale to create meaningful global deterrence. Our other product, which I can’t discuss as freely, is further along and has successfully executed a full flight on a military test range. We can produce five prototypes of this product a day and will look to 100x that number over the coming years.

Overall, we’ve burned less than 15% of the money we raised, have ultra-clear customer support, and have rallied a small, incredibly mission-oriented team of 45 of the world’s best operators, engineers, and manufacturers. I was working out of a dorm room 15 months ago. Today, I write this from our 115,000 sqft factory, where I work alongside people I deeply admire to develop world-changing products for war-fighting customers.

Though I’m proud of our progress, the path ahead will be very hard. We’re building an incredibly difficult company, and as with most startups, the chance of failure is high. As a 1-year-old business, we’ve made many mistakes, but as part of our culture, we work to fix them, learn from them, and relentlessly improve. I’m more confident than ever that we can achieve our goals, and we’ll keep fighting to deploy prolific and capable platforms to help fend off future conflicts.

Mach Industries - Member